OUR PROCESS

rave against the machines

Craft cider has always been a sustainable product.

The drink with the ultimate recycle:

It was traditionally made from ‘rebut’ apples and the pomace (waste) was used as compost or as animal feed.

It can hardly be more exemplary.

At Anargist we work according to that traditional circle.

The fruit we use would otherwise go to waste.

We pick and wash it with our hands.

We press it with our muscles and we use as little electricity as possible.

The microorganisms do their job and we facilitate.

Nothing – really nothing – is added to the ciders.

Our pomace is composted and returned to nature.

We avoid using large machines.

Just like fermentation in plastic.

That may sound a bit puritanical, labour-intensive,

hippie, old-fashioned…

But Anargist wants to stay as small as possible to offer truly sustainable traditional ciders.

By staying small, we can guarantee quality and origin, the fruit does not have to come from further afield and we can continue to work manually.

A market in which the sharpest elbows are rewarded and economic growth takes precedence always comes at the expense of quality, the local economy and sustainability.

That is why we advocate a rich landscape full of small artisan local makers who each manufacture a unique product of higher quality and thus strengthen each other and their own sector.

FERMENTATION

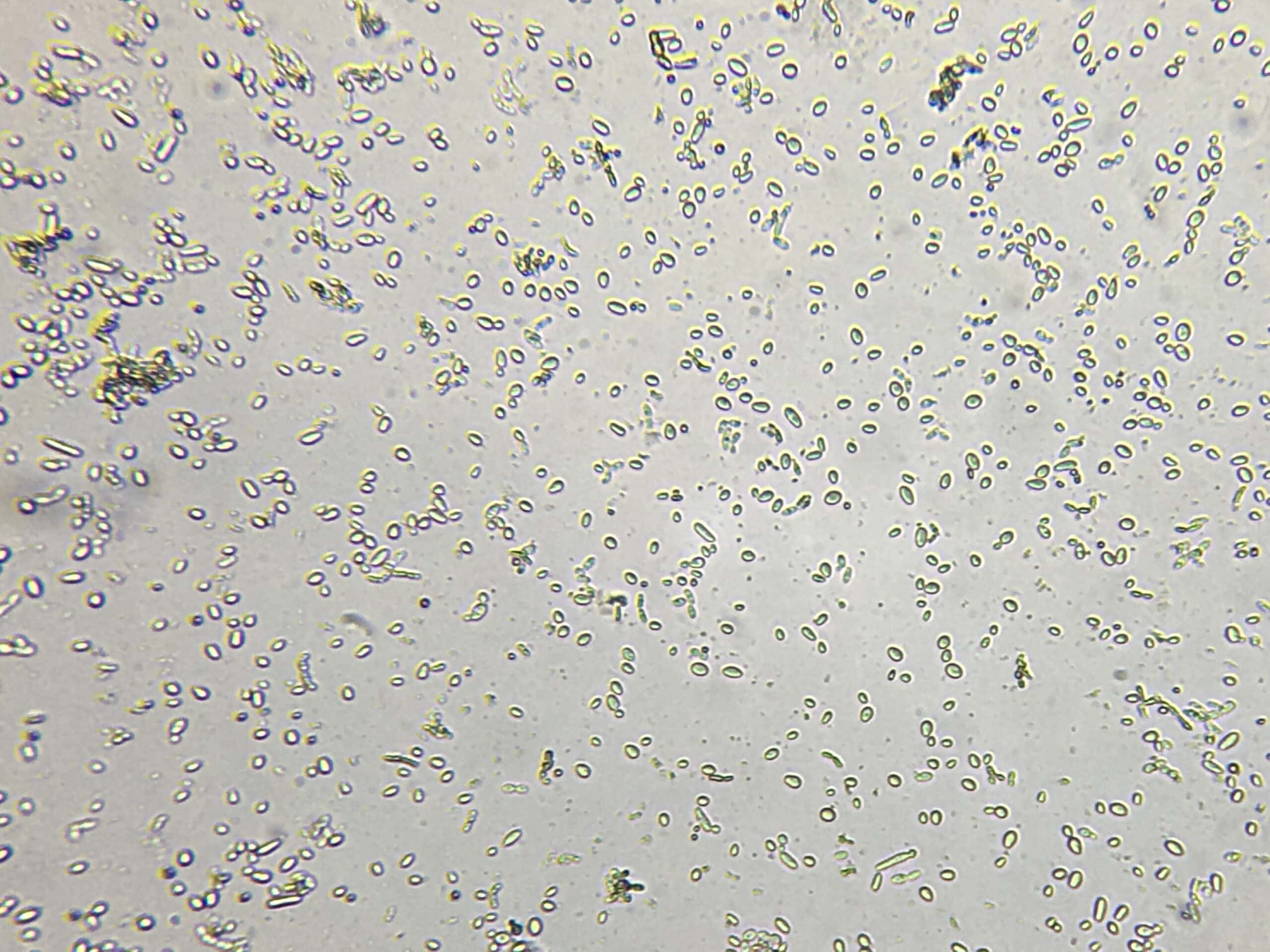

Anargist does not add commercial yeasts to the ciders.

We work with the wild, local yeasts and bacteria to ferment our juice.

After all, they are everywhere.

On the trees, the fruit, the tools and some in the air.

Our ciders are therefore made next to the orchard, surrounded by flowers and plants.

This creates a unique, local cocktail of microorganisms.

Those are the real cider makers.

They slowly ferment the juice during the winter.

And because they are all different, they create a complexity of aromas.

We do the mis-en-place, they are the chefs.

We just keep a careful eye on them during the process.

And that means a lot of measuring and tasting.

Until we think it’s time for

bottling, further maturation, blending..

And then the process continues.

Natural cider remains a living product, even in the bottle.